PRODUCTS

X Rings

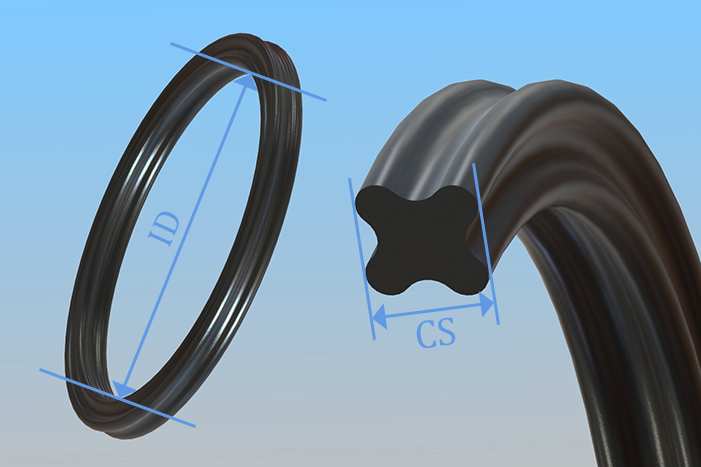

X-Rings, with their distinctive star-shaped design, are engineered to surpass the capabilities of traditional O-rings by offering double the sealing surface area. This design ensures enhanced stability and significantly reduces the risk of twisting and rolling during operation. Ideal for high-pressure and high-speed environments, X-Rings provide reliable sealing under demanding conditions.

These seals are particularly effective in dynamic applications across various industries, including hydraulic systems, automotive applications, and industrial machinery where consistent performance and durability are critical. The unique four-lobed design of X-Rings allows for better pressure distribution, minimizing the potential for seal failure and making them a preferred choice for challenging sealing tasks.

X-Rings are suitable for both static and dynamic applications, offering a wide range of uses from flanges and valves to light-duty cylinders. They are an economical sealing solution for low-pressure systems and can be produced from materials like FKM to meet high-temperature or chemical resistance requirements.

PRODUCT DETAILS

X-Rings, known for their star-shaped design, are engineered to provide superior sealing capabilities for dynamic applications across various industries. These seals are designed to offer twice the sealing surface area of traditional O-rings, ensuring enhanced stability and reduced risk of twisting and rolling during operation. Ideal for use in high-pressure and high-speed environments, X-Rings maintain a reliable seal under demanding conditions.

1.Key Features of X-Rings

Enhanced Stability

X-Rings have a non-circular cross-section, which avoids rolling during reciprocating motion. This design provides higher stability compared to O-rings, making them suitable for dynamic applications where traditional seals might fail.

Double-Acting Four-Lip Seals

X-Rings are double-acting four-lip seals with a practically square cross-section profile. They achieve their sealing effect when built and pressed into an axial or radial installation space. During operation, the media pressure reinforces the sealing function, ensuring a tight seal.

Material Flexibility

X-Rings can be produced from various elastomer materials, including FKM, which is suitable for high-temperature or chemical resistance requirements. This flexibility allows for tailored solutions to meet specific industry needs.

Low Friction

Compared to O-rings, X-Rings offer low friction, which is beneficial in applications where reduced energy consumption and wear are important.

2.Applications of X-Rings

Hydraulic and Pneumatic Systems

X-Rings are widely used in hydraulic and pneumatic static applications, providing reliable sealing in systems that require consistent performance and durability.

Flanges and Valves

In flange and valve applications, X-Rings ensure a tight seal, preventing leaks and maintaining system integrity.

Light Duty Cylinders

X-Rings are also used in light duty cylinders, where their low friction and high stability provide an economical sealing solution for low-pressure applications.

3.Advantages of X-Rings

Suitable for Static and Dynamic Applications

X-Rings are versatile and can be used in both static and dynamic applications, making them a flexible choice for various sealing needs.

Wide Application Area

Their wide application area includes automotive, aerospace, and industrial machinery, where consistent performance and durability are critical.

No Twisting in the Housing

The unique design of X-Rings prevents twisting in the housing, ensuring a reliable seal and reducing the risk of seal failure.

Economical Sealing Solution

For low-pressure applications, X-Rings provide an economical sealing solution that offers high performance at a lower cost.

4.How to Choose the Right X-Ring

Material Selection

Choose the appropriate material for your X-Ring based on the specific requirements of your application, including temperature, pressure, and chemical resistance.

Size and Specification

Ensure that the X-Ring's size and specification match the dimensions of your sealing application. Proper fit is essential for achieving a reliable seal.

Operating Conditions

Consider the operating conditions of your application, including pressure, temperature, and fluid type, to select the most suitable X-Ring for your needs.

Conclusion

X-Rings offer an advanced sealing solution for dynamic applications, providing twice the sealing surface area of traditional O-rings and ensuring enhanced stability and reduced risk of twisting and rolling during operation. Their unique four-lobed design allows for better pressure distribution and minimizes the potential for seal failure, making them a preferred choice for challenging sealing tasks. Whether you are working in hydraulic systems, automotive applications, or industrial machinery, X-Rings provide a reliable and durable sealing solution that meets the demands of your specific applications.