product list

Products

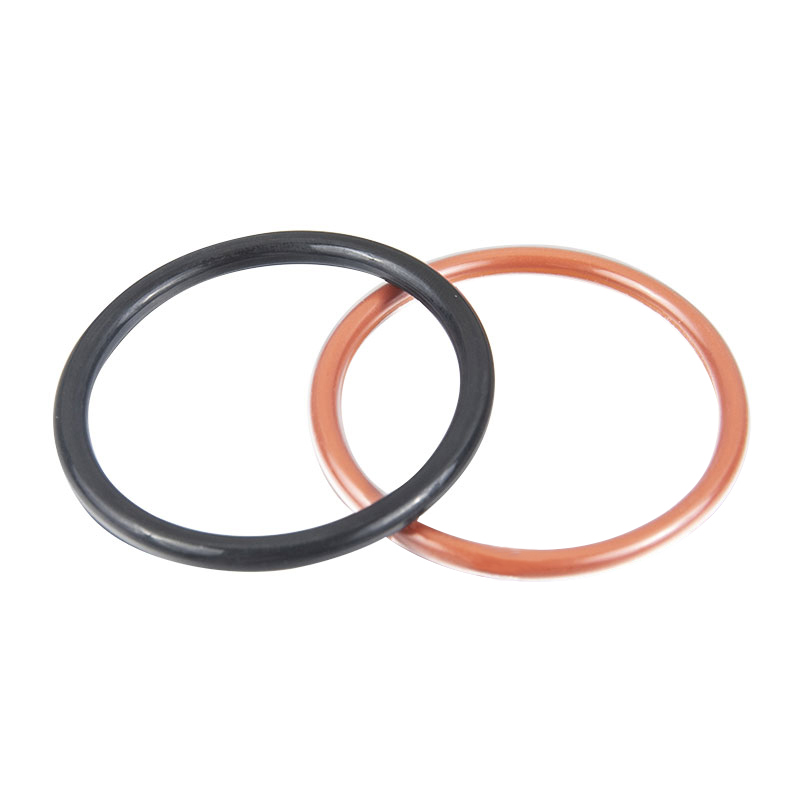

PTFE Coated O-Ring

PTFE Coated O-Rings provide an enhanced sealing solution by integrating the flexibility of rubber O-rings with the chemical resistance of PTFE. This composite design offers superior performance in extreme chemical environments, reducing friction and wear while extending the seal's lifespan. Ideal for applications requiring high cleanliness, such as food processing and pharmaceuticals, these O-rings feature a broad temperature range and excellent non-stick properties. They are the perfect choice for challenging sealing tasks where reliability and durability are paramount.

FEP/PFA Encapsulated O-Rings

FEP/PFA Encapsulated O-Rings combine the elasticity and stability of elastomer cores (such as silicone or FKM) with the chemical resistance of fluoropolymer (FEP/PFA) coatings. The elastomer core provides essential mechanical properties, while the seamless FEP/PFA encapsulation ensures reliable sealing and high resistance to corrosive media. These O-Rings are designed for low-pressure static or slow-moving dynamic applications and are best suited for non-abrasive contact surfaces and media. They require low assembly forces and limited elongation, ensuring easy installation and long-term performance. This makes them ideal for industries requiring high chemical resistance and purity, such as pharmaceuticals, food processing, and semiconductor manufacturing.

ED Rings

ED ring is a high-performance sealing element, widely used in the sealing of pneumatic and hydraulic joints such as pipe joints, hydraulic plugs, transition joints, and also suitable for threaded oil ports and screw ends. It is mainly used for static shaft sealing. Even under high pressure, its cross-sectional shape can remain stable, and the sealing effect is better than that of traditional O-rings. ED rings are made of high-quality materials, among which nitrile rubber (NBR) is suitable for the temperature range of -40℃ to 120℃, while fluororubber (FKM) is suitable for the temperature range of -20℃ to 200℃. ED rings are wear-resistant, high-pressure-resistant, oil-resistant and high-temperature-resistant. In addition, its advantages include high mechanical stability, good pressure adaptability, long-lasting sealing performance and high-pressure tolerance up to 60MPa.

Silicone O-rings

Silicone O-Rings are made from silicone rubber, a material known for its flexibility and resilience. These O-Rings are particularly useful in applications requiring resistance to extreme temperatures, ranging from -70°C to +220°C, and exposure to weather elements, making them ideal for outdoor equipment and automotive use. They also exhibit excellent resistance to ozone, UV light, and various chemicals, which extends their service life in diverse environments. Silicone O-Rings are commonly used in sealing applications within the medical, food processing, and aerospace industries due to their non-toxicity and FDA compliance. Their ability to maintain a tight seal in both static and dynamic conditions ensures reliable performance across a broad spectrum of uses.

PTFE O-Rings

PTFE O-Rings are precision-engineered seals renowned for their exceptional chemical resistance and low friction properties. These O-Rings are ideal for applications involving aggressive chemicals, high temperatures, and environments where contamination must be minimized. They offer a wide operating temperature range and are virtually non-stick, ensuring consistent performance across various industries, including chemical processing, pharmaceuticals, and semiconductor manufacturing.The smooth surface finish of PTFE O-Rings contributes to their long service life by reducing wear on mating surfaces. They are also known for their high purity, making them suitable for use in food and beverage applications where FDA compliance is required. PTFE O-Rings are a reliable choice for sealing solutions that demand durability, cleanliness, and resistance to harsh conditions.

X Rings

X-Rings, with their distinctive star-shaped design, are engineered to surpass the capabilities of traditional O-rings by offering double the sealing surface area. This design ensures enhanced stability and significantly reduces the risk of twisting and rolling during operation. Ideal for high-pressure and high-speed environments, X-Rings provide reliable sealing under demanding conditions.

These seals are particularly effective in dynamic applications across various industries, including hydraulic systems, automotive applications, and industrial machinery where consistent performance and durability are critical. The unique four-lobed design of X-Rings allows for better pressure distribution, minimizing the potential for seal failure and making them a preferred choice for challenging sealing tasks.

X-Rings are suitable for both static and dynamic applications, offering a wide range of uses from flanges and valves to light-duty cylinders. They are an economical sealing solution for low-pressure systems and can be produced from materials like FKM to meet high-temperature or chemical resistance requirements.

Perfluoroelastomer (FFKM) O-Rings

Perfluoroether rubber is a preferred sealing material for high-end manufacturing and extreme working conditions. Its high performance makes it perform well in demanding applications. FFKM has excellent temperature adaptability (-10℃ to 320℃) and unparalleled chemical resistance. It also has excellent resistance to gas and liquid permeation, weather resistance, ozone resistance, and self-extinguishing properties, ensuring safety and reliability under extreme conditions. Its high density and good mechanical properties further enhance the sealing effect and are suitable for scenes with explosive decompression, CIP, SIP and FDA requirements.

Application scenarios

Chemical and petrochemical industries: used for reactors, pumps and valves, resistant to highly corrosive chemicals.

Semiconductor industry: high purity and chemical resistance make it ideal for etching and cleaning processes.

Oil and gas industry: used for well seals and valves, adapting to extreme chemical and thermal conditions.

Electronics Industry: Meet the requirements of high-performance electronic products for chemical resistance and thermal stability.

Fuel Cells: Used for battery pack sealing to ensure no leakage and improve efficiency.